How can GelMA support tissue engineering and organ reconstruction?

Biomaterials are an integral part of the tissue engineering process, providing a nurturing environment for cell growth and tissue regeneration. Gelatin methacryloyl (GelMA or GelMOD) is an extremely versatile biomaterial that allows the formation of 3D architectures that mimic the native extracellular matrix, allowing cells to grow, interact and differentiate.

Rousselot has developed a premium gelatin methacryloyl hydrogel, X-Pure® GelMA, which has been specifically designed to support regenerative medicine and tissue engineering and accelerate clinical translation.

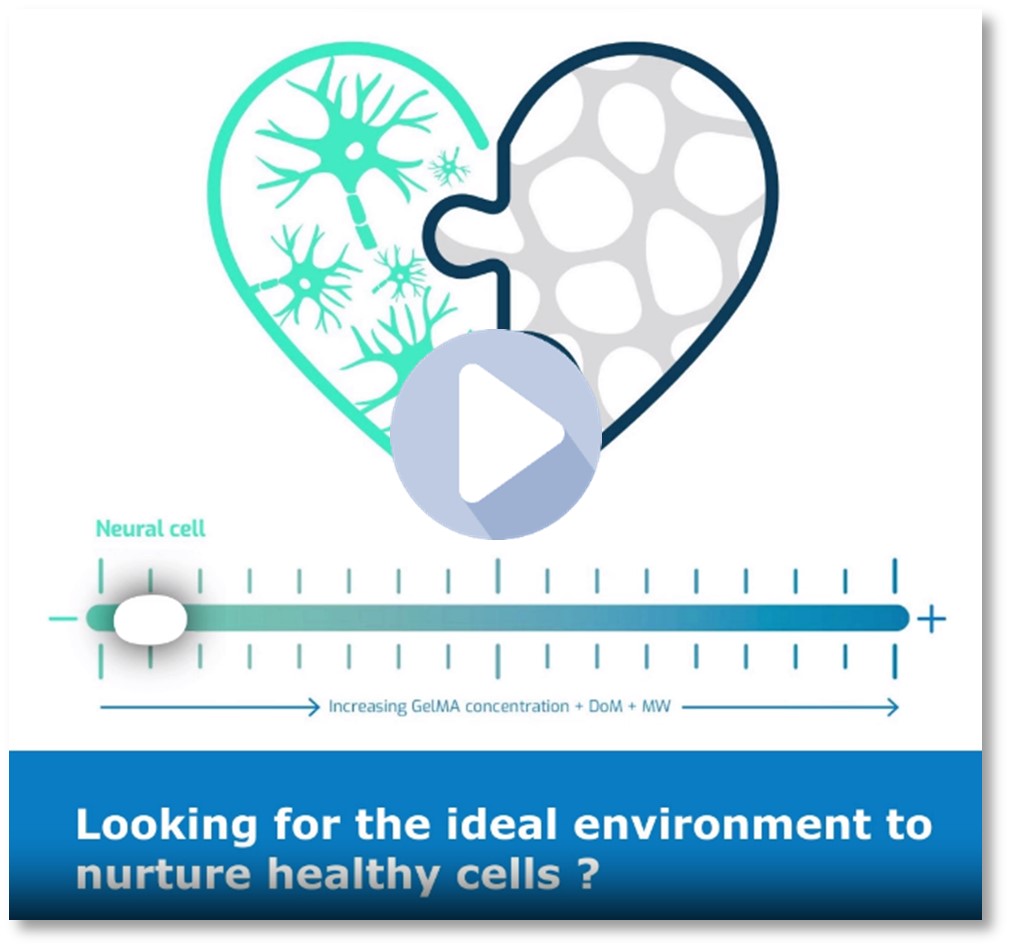

Watch our video hosted on YouTube:

What is X-Pure GelMA?

X-Pure GelMA is the world’s first one produced under GMP conditions(1), making it suitable for clinical use in advanced biomedical applications.

Crucially, different cells require different environments. Therefore, it is essential to choose a biomaterial that can be tailored to the specific cell or tissue type to ensure an ideal “GelMAtch"!

Benefit from the tunable properties of GelMA hydrogels: X-Pure GelMA can be customized by varying the degree of functionalization (DoM) and molecular weight (MW) or adjusted to the intended application, making it one of the most versatile hydrogels available for 3D cell culture and drug delivery systems(2).

How to choose the perfect GelMA?

To select the best GelMA for your application, it is important to keep these three characteristics in mind:

- Consistent quality to make your research repeatable, reproducible and translatable

- Functional equivalence between research & GMP grades, reducing development timelines

- Ultra-purified, providing an environment where cells can thrive (≤ 10EU/g endotoxin)

Why does purity matter for biomaterials?

A major factor to consider when a biomaterialfor tissue engineering is the presence of contaminants. Endotoxins or chemical residuals can have deleterious effects, leading to altered cellular responses and misinterpretation of results. For this reason, all products in Rousselot’s X-Pure range of pharmaceutical gelatins are purified to ensure ultra-low impurity levels.

The use of purified gelatin can speed up the transfer from bench to clinic by reducing the variability of your data, increasing reproducibility and enabling you to avoid regulatory hurdles in further development. Ultimately, choosing purified gelatins can help to make your product safer and accelerate your path to market.

[1] IPEC. Excipient Good Manufacturing Practices Guide, 2017 (link to be checked)

[2] Pepelanova, I., Kruppa, K., Scheper, T. and Lavrentieva, A., 2018. Gelatin-Methacryloyl (GelMA) hydrogels with defined degree of functionalization as a versatile toolkit for 3D cell culture and extrusion bioprinting. Bioengineering, 5(3), p.55